The Achilles academia-industry research programme focused on the deterioration of geotechnical assets supporting key infrastructure has shared its findings with the industry.

The five year Achilles research programme, funded by the Engineering & Physical Sciences Research Council, came to an end last year. It culminated in a finale event in London in late November.

Achilles was a partnership between researchers from six universities – Newcastle, Loughborough, Durham, Southampton, Bath and Leeds – the British Geological Survey, asset owners and industry consultants.

It aimed to better understand the deterioration of long linear assets – embankments and cuttings – underpinning the UK’s transport and flood protection infrastructure.

The UK’s transport infrastructure is among the most heavily used in the world and much of its rail network in many parts is more than 100 years old. As a result, failure of earthworks can significantly impact safety, cause delays, affect the environment, and incur high financial costs.

Achilles has looked at why failures occur in certain areas and at specific times. As, for example, similar rainfall events might not have triggered failures on the same earthworks before, and failures are more common on older assets.

“What is causing all of that?” Newcastle University civil engineering professor Stephanie Glendinning asked the audience at the finale event. “The understanding that we have as an academic team and as a set of industrialists, how can we use our knowledge – plus the advances in data and digital technologies – to work together to develop the tools that we need to better understand the reasons why those things happen?”

The programme has thus been focused on developing tools that are needed to design, construct and invest in a sustainable and resilient transport system for the future at an affordable cost.

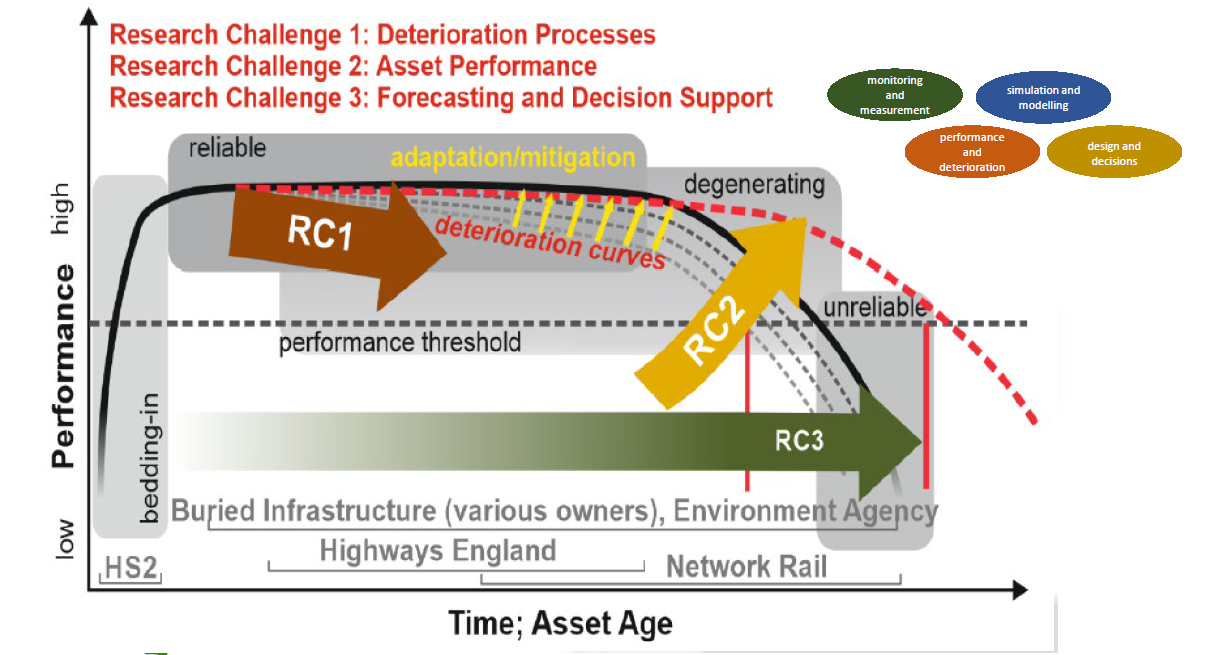

The concept of Achilles has been formulated around the below diagram:

“The diagram is saying that as an asset ages, in its early construction, it takes a bit of time to reach its peak performance, and performance can be measured in various different ways. It could be measured in terms of factor of safety against failure, safety more broadly or delivery of service. We’ve tended to use factor of safety, but not exclusively,” Glendinning said.

“And then over a period of time that asset then performs as we wish it to perform. But all the while deteriorating, so it’s losing performance. And the reasons why this performance has been lost, we’ve postulated is because of impacts of weather and climate on the deterioration of the materials that make up those assets.

“At some point, the asset no longer falls within the standard that we would accept, whether that’s through safety or serviceability. And you can see that we’ve got that indication of constant deterioration. But then there’s the idea that we could intervene in these assets at various different points, in order to alleviate that deterioration and bring that asset back up to its peak performance again, extending the life of that asset, and therefore improving the sustainability of the assets by not having to renew.”

The questions the team needed to answer included: Can we better understand the reasons and the processes of deterioration, so we could define those lines of deterioration on the asset? Could we then look at how that deterioration affects the performance of the asset? Can we model it, and can we model it effectively? Can we measure it out in the field, so that we can determine where on the performance curve that asset sits? And then can we use that knowledge and the understanding of the material in the asset to be able to create some tools to help forecast future performance and to work out when it is best to intervene from a technical and financial point of view? Can we help our stakeholder partners make decisions in that context?

In terms of investigating the deterioration process, Achilles has focused on clay materials at the higher end of the plasticity scale. Climate change and more extreme weather events are expected to increase the rate of deterioration in these high plasticity soils.

“We put those materials through wetting and drying cycles that you might get through summer and winter, but we’ve also modelled those as we’re experiencing climate change and looking at larger cycles of wet and dry in the future,” Glendinning added.

The repeated wetting and drying of the soil will cause irreversible deterioration. The deteriorating clay then loses suction because of the breaking up of the material, which can be measured in the laboratory and the field. The wetting and drying also cause soils to soften, which climate change accelerates.

“We’ve looked then to incorporating that understanding into what we have done in terms of asset modelling of the slopes – both cuttings and embankments – and what we’ve done in terms of field observation. We found using those numerical tools that the critical failure surface changes with time due to deterioration. In a cutting, as it ages, the surface deteriorates and we get shallower critical failure surfaces occurring. That’s what we’ve seen out there on the assets,” she explained.

“The geometry of the slope influences that long term behaviour. The steeper the slope, the more likely it is you get a deeper rotational failure; the shallower it is the more likely is it to be a downslope ratcheting failure.”

Other points highlighted regarding asset deterioration included:

- wetter-than-average years lead to increased annual slope movements

- deterioration reduces the trigger threshold at which an asset will fail

- climate change will reduce the time-to-failure to about half that of present climate conditions.

Design life

As presented at the finale event, the Achilles team has worked on improving the collective understanding of the impacts of climate change on the physical resilience of clay assets. It has developed a toolbox of assessment techniques to determine asset conditions and to simulate the processes.

As shown in Glendinning’s presentation, for design of slopes in high plasticity materials:

- design pore water pressures need not increase

- shallow seasonal ratcheting can mobilise low frictional strengths.

For interventions aimed at extending life:

- for new assets, early intervention provides the greatest extension, but later intervention gives lower discounted whole-life costs

- climate change reduces the resilience of earthworks and increases the need for earlier interventions, but many of our assets are already old.

The tools aid in bringing design life and time to failure into slope design and stability assessment.

Design life is defined in the Eurocodes as “the assumed period for which the structure or part of it is to be used for its intended purpose with anticipated maintenance but without major repair being necessary”.

Eurocode 0 classifies five different design life categories, with High Speed 2, for example, fitting into category 5. This covers “monumental buildings, bridges and other strategically important civil engineering structures” with a design life of 120 years.

Talking at the event, HS2 Ltd head of geotechnical engineering Nick Sartain said: “That’s important, because once you know the design life you’re designing for, it enables you think about things around loading that you should be anticipating for you structure, about resistance that you need, about how much it should cost, materials you want to use, about sustainability, about carbon.

“If you ask any of our designers on HS2 what the design life is going to be, the answer is straight away 120 years, because it tells us that in the Eurocodes. If you ask them, what is the period that that structure will actually last, don’t expect them to answer at all, because it’s essentially imponderable.

“Because as it says in the Eurocode, the working design life is indicative. Nothing really about the Eurocode explicitly ensures that either that design life will be achieved or that the asset you design won’t exceed that design life.”

While other engineers create assets like mobile phones or cars that have a design life that correlates with their operational life, it is different for infrastructure engineers as the operational life of the assets is “kind of unspecified”.

“And the reason is because of this sort of systems thinking. We’re responsible for the design, the maintenance and the upkeep of an integrated system with a lot of assets, each of which have their own degradation characteristics. But in combination, we, the society, expect them to deliver something that works kind of in perpetuity,” Sartain added.

“On average, the underlying fundamental assets which support that structure essentially appreciate in value. The value to society of your embankment or your cutting is far greater than the intrinsic value of the cost of that asset itself. The value to society is the thing that’s really important.

“So essentially, we’re in a place where although we all understand that our earthworks assets wear out, they’re kind of not allowed to become obsolete.”

While the design working life is embedded in design codes, climate change will have a fundamental impact on the assets’ performance.

As such, Sartain concluded that additional evidence about the long-term performance of high-plasticity clay slopes is vital, and that the work of Achilles increases the opportunity for a paradigm shift in design approaches.

Reading guides

The Achilles programme grant team wanted to produce outputs that are of real use to practitioners and digestible for non-academics. The papers based on the programme’s findings have thus been summarised in a selection of reading guides.

Digital copies of the Achilles Reading Guides are available here.

The reading guides will be further summarised in upcoming issues of GE.